Everything You Need to Know About Preformed Thermoplastic Paint

Introduction: Why Preformed Thermoplastic Matters Now

If you’ve ever cycled through a busy city or driven late at night, you know how critical road markings are. They don’t just guide traffic — they protect lives. But traditional road paints fade quickly, often requiring frequent reapplication, which adds cost, labor, and downtime.

This is where preformed thermoplastic comes in. It’s a ready-to-use, highly durable material that has revolutionized the way we approach road safety and infrastructure. In this guide, we’ll cover everything — what it is, how it’s used, its benefits, costs, comparisons with alternatives, and what the future looks like.

Whether you’re a contractor, municipal planner, or facility manager, this is the ultimate reference for preformed thermoplastic.

What Is Preformed Thermoplastic?

Preformed thermoplastic is a type of road marking material that comes pre-cut into shapes or symbols such as arrows, bike symbols, and crosswalk lines. Unlike liquid paints, it’s manufactured under controlled conditions to ensure consistency, visibility, and durability.

Key characteristics:

- Ready-to-use, no need for large melting kettles.

- Pre-cut into arrows, letters, numbers, logos, and crosswalk strips.

- Strong adhesion to asphalt and concrete when heated with a torch.

- Designed for high reflectivity and skid resistance.

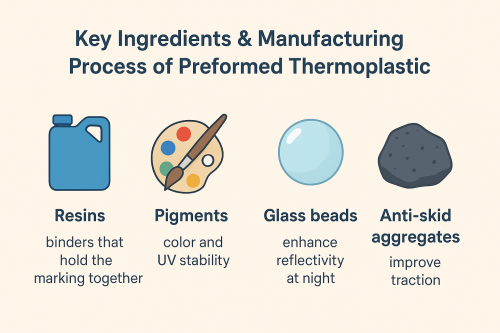

Key Ingredients & Manufacturing Process

Preformed thermoplastic is composed of:

- Resins – binders that hold the marking together.

- Pigments – color and UV stability.

- Glass beads – enhance reflectivity at night.

- Anti-skid aggregates – improve traction.

Difference from Traditional Thermoplastic Paint

☑️ Preformed: Applied with a propane torch, no melting kettles required, easy for small or detailed projects.

☑️ Hot-applied thermoplastic: Requires specialized equipment, better suited for large-scale highway projects.

Benefits of Preformed Thermoplastic in Road Projects

1. Durability & Longevity

A study by the Swedish Transport Agency (2023) found that preformed thermoplastic markings lasted 6–8 years in high-traffic zones, compared to just 1–2 years for paint.

2. Enhanced Visibility

Because of the embedded glass beads, preformed thermoplastic provides exceptional night-time visibility. According to the Federal Highway Administration (FHWA, 2023), reflective thermoplastic markings reduce nighttime crashes by up to 25%.

3. Cost-Efficiency & Lifecycle Value

While the initial cost is higher than paint, the overall lifecycle cost is lower:

- Paint: cheap but needs yearly reapplication.

- Performed thermoplastic: longer lifespan, less labor, lower maintenance.

4. Sustainability Factors

- Lower VOC emissions compared to solvent paints.

- Recyclable packaging.

- Complies with ESG reporting standards, making it attractive for public-private projects.

Applications of Preformed Thermoplastic Across Industries

1. Roadways & Highways

Used for lane dividers, pedestrian crossings, and arrows. Its fast application reduces lane closure times.

2. Urban Mobility & Bike Lanes

In fast-growing cities, bike lanes are critical for sustainable mobility and commuter safety. Traditional painted bike symbols often fade after just a few months, making them less visible to motorists and cyclists alike.

With preformed thermoplastic markings, cities like Amsterdam, Copenhagen, and Berlin have achieved long-lasting, high-visibility cycle paths that remain clear even after years of heavy use and harsh weather.

👉Learn more about Thermoplastic Road Marking Paint Applications.

From my own experience as a cyclist navigating urban environments for over a decade, I’ve noticed how thermoplastic markings stay vibrant and skid-resistant, providing an extra layer of confidence compared to faded paint lines that often blur into the asphalt. This consistency not only improves safety but also encourages more people to adopt cycling as a daily mode of transport.

3. Airports & Logistics Hubs

Airports demand highly durable markings. According to ACI World, Dubai International Airport uses thermoplastic on runways to reduce maintenance downtime.

4. Commercial & Industrial Facilities

- Warehouses: forklift lanes, safety zones.

- Parking lots: arrows, reserved spots.

- Industrial plants: hazard and fire lanes.

Installation Process of Preformed Thermoplastic

Tools & Preparation Needed

- Propane torch or heat gun

- Broom or blower for cleaning

- Primer for concrete or polished asphalt surfaces

Step-by-Step Installation

- Surface Preparation: Clean surface to remove debris, oil, or dust.

- Positioning: Lay pre-cut markings accurately.

- Priming: Optional, for concrete or polished asphalt.

- Heating: Use propane torch, maintain even heat to melt and bond.

- Cooling: Allow markings to set before traffic resumes.

Safety Measures

✅ Wear PPE: gloves, goggles, flame-resistant clothing.

✅ Have fire extinguishers nearby.

✅ Avoid installation in windy or wet conditions.

Common Mistakes & Fixes

❌ Mistake: Applying on damp or oily surface → Fix: Thoroughly clean and dry.

❌ Mistake: Uneven heating → Fix: Use sweeping motion for uniform melting.

❌ Mistake: Overheating → Fix: Maintain correct torch distance.

Comparing Preformed Thermoplastic with Alternatives

| Material Type | Lifespan | Initial Cost | Maintenance | Visibility |

| Road Paint | 1–2 yrs | Low | High | Low |

| Hot-Applied Thermoplastic | 3–5 yrs | Medium | Medium | High |

| Preformed Thermoplastic | 6–8 yrs | High | Low | Very High |

Challenges and Limitations of Preformed Thermoplastic

- Upfront Cost: Higher initial investment than paint.

- Surface Requirements: Doesn’t adhere well to cracked or oil-soaked asphalt.

- Climate Sensitivity: Cold temperatures reduce flexibility during installation.

- Supply Constraints: Limited availability in some regions may affect lead times.

Future Trends & Innovations

- Smart Road Markings: Thermoplastic embedded with sensors for autonomous vehicle navigation.

- Eco-Friendly Materials: Biodegradable resins, recycled aggregates, and low-VOC formulations.

- Customizable Designs: City logos, pedestrian symbols, and branded bike lanes.

- Global Adoption: EU Horizon Road Safety Program and Vision Zero initiatives increasingly mandate reflective, durable road markings.

Data Insight: Cities investing in durable thermoplastic markings report 20–30% reductions in maintenance costs over a 5-year period compared to paint.

Conclusion:

Preformed thermoplastic is no longer a niche material—it’s a global standard for durable, visible, and sustainable road markings. Whether for highways, bike lanes, airports, or industrial sites, it improves safety, reduces maintenance costs, and supports ESG initiatives.

👉 For expert guidance on installing preformed thermoplastic, contact Prime Roads and future-proof your infrastructure today.

For durable, high-visibility, and long-lasting road markings, Prime Roads is the best thermoplastic paint manufacturer. Their premium materials, precise pre-cut designs, and expert support make them the top choice for highways, urban lanes, airports, and industrial facilities.

FAQ about Preformed Thermoplastic

How long does preformed thermoplastic last?

Preformed thermoplastic typically lasts 6–8 years, depending on traffic volume, climate, and surface conditions. Its durability far exceeds traditional road paint, making it a cost-effective, long-term solution for highways, urban roads, airports, and industrial facilities.

Can it be applied on concrete?

Yes, preformed thermoplastic can be applied on concrete surfaces. For optimal adhesion, a primer is recommended, especially on polished or smooth concrete, ensuring long-lasting performance even in high-traffic areas.

Is preformed thermoplastic eco-friendly?

Yes. Preformed thermoplastic has low VOC emissions compared to solvent-based paints and often comes in recyclable packaging, making it a more sustainable choice for municipalities and environmentally conscious projects.

How is it different from road paint?

Unlike traditional paint, which typically fades within 1–2 years, preformed thermoplastic can last up to 8 years. It maintains high reflectivity, skid resistance, and color vibrancy, reducing the need for frequent maintenance and improving overall road safety.

Can logos or custom designs be created?

Yes. Manufacturers can produce custom-cut symbols, logos, and shapes tailored for bike lanes, pedestrian zones, schools, airports, or commercial facilities, offering both functional and branded road markings.