Glass beads: The Key to Reflective and Durable Traffic Paint for Road Markings

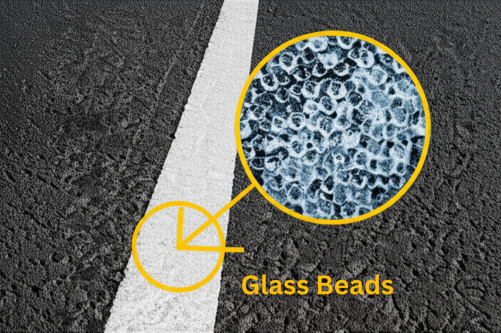

Road markings are more than just white or yellow lines on the road. They guide drivers at night, during rain, or in fog. But have you ever wondered why some road markings shine brightly when vehicle headlights hit them? The secret is glass beads. These tiny, clear spheres are mixed with traffic paint to make road markings reflective and long-lasting.

In this blog, let’s break down why glass beads are important, how they work, and why contractors should choose the right traffic paint with beads for safe and durable road markings.

Introduction to Glass Beads

Glass beads are tiny, round balls made from recycled or special industrial glass. They are smooth, transparent, and very durable. Their size is usually less than 1 millimeter, but they make a big difference when used in traffic paint for road markings.

Two main purpose of Glass beads:

- Reflectivity – They bounce light back to drivers, making road lines visible at night.

- Durability – They add strength to the paint layer, helping it last longer under heavy traffic.

High Reflective Glass Beads for Traffic Paint

When we talk about glass beads in road markings, most people only think of them as shiny “add-ons” to paint. But in reality, these microscopic spheres are the invisible engineers of road safety.

Unlike ordinary paint that fades into the darkness after sunset, glass beads transform road markings into self-illuminating guides. When glass beads mixed with traffic paint or sprinkled on top of freshly painted lines, they make the road markings glow when light falls on them. This simple addition turns normal paint into reflective paint, which is very helpful for drivers at night.

As a reflective glass beads manufacturer and supplier, we use top-grade glass raw materials to ensure durability, clarity, and performance. Our products meet international standards and are exported to several countries worldwide.

Key Specifications of glass beads:

-

Specific Gravity: 2.4 – 2.6 g/m³

-

Stacking Density: 1.5 g/cm³

-

Roundness Rate: ≥ 80%

-

Refractive Index: 1.5 – 1.6

These high-quality glass beads are suitable for thermoplastic paint, water-based paint, and solvent-based road marking paint, ensuring long-lasting performance on highways, city roads, airports, and parking areas.

Working Process of Glass Beads

- When a car’s headlights shine on the road, the glass beads act like tiny mirrors.

- The light enters the bead, bends inside it, and bounces back towards the driver.

- This effect is called retroreflection.

This makes the road markings look bright and visible at night. As the top beads wear out with traffic, new beads embedded in the paint surface get exposed, ensuring continuous visibility.

Chemical Composition of Glass Beads

| Component | Typical Content (%) | Function in Road Marking Glass Beads |

|---|---|---|

| SiO₂ (Silicon Dioxide) | 68 – 75% | Provides strength, transparency, and hardness |

| Na₂O (Sodium Oxide) | 10 – 14% | Acts as a flux, lowers melting temperature |

| CaO (Calcium Oxide) | 6 – 12% | Improves chemical durability and stability |

| MgO (Magnesium Oxide) | 0 – 4% | Enhances resistance to weather and abrasion |

| Al₂O₃ (Aluminium Oxide) | 0 – 2% | Increases hardness and chemical resistance |

| Fe₂O₃ (Iron Oxide) | ≤ 0.5% | Present in trace amounts, can influence color |

| Other Oxides (K₂O, BaO, TiO₂, etc.) | ≤ 2% | Stabilizers and processing aids |

Why Are Glass Beads Important for Road Contractors?

For a contractor or road builder, road markings are not just about painting lines. They are about safety, durability, and quality work.

Using thermoplastic traffic paint without glass beads can cause:

❌ Road markings that fade quickly.

❌ Poor visibility at night, leading to accidents.

❌ Extra maintenance costs because the lines need repainting often.

Traffic road marking paint with good quality glass beads ensures:

✅ Clear, visible markings day and night.

✅ Long-lasting performance.

✅ Satisfied clients and strong reputation.

Benefits of Reflective Glass Beads in Traffic Paint

Here are the main advantages explained in simple words:

- Better Safety – Drivers can see the markings clearly even in low light.

- Longer Durability – Paint lasts longer because beads protect the surface.

- Cost-Effective – Less repainting means saving money on maintenance.

- Professional Finish – The road looks neat, bright, and well-maintained.

Types of Glass Beads Used in Road Markings

Different roads require different solutions. Contractors often choose from the following types:

Drop-On Beads

- Sprinkled directly on the freshly applied paint or thermoplastic surface.

- Provide immediate reflectivity because they sit on the surface.

- Ideal for quick projects like pedestrian crossings or city road lines.

Intermix Beads

Intermix Beads

- Mixed into the traffic paint before application.

- As the paint wears off over time, new beads get exposed layer by layer.

- Ensures long-term reflectivity and durability.

- Best for highways and roads with heavy traffic.

Premix Beads

Premix Beads

- Added to thermoplastic paints before they are melted and applied.

- Offer both surface reflection and embedded protection.

- Commonly used in durable road marking solutions.

High-Performance Beads

- Larger and brighter than normal beads.

- Designed for places that demand maximum visibility like highways, expressways, and airport runways.

- Can handle heavy traffic pressure and last longer.

Colored Glass Beads (Special Use)

- Some projects require beads that are coated or tinted to match specific colors (e.g., red or yellow markings).

- Used in specialized zones like bus lanes, cycle tracks, or industrial areas.

Where Are Glass Beads Used in Road Markings?

Glass beads are used almost everywhere road markings are needed:

✅ Highways and expressways

✅ City roads and pedestrian crossings

✅ Parking lots and industrial areas

✅ Airports runways and taxiways

Wherever visibility is critical, glass beads in traffic paint make a big difference.

Common Problems When Glass Beads Are Not Applied Correctly

Sometimes road markings fail not because of the paint but because the beads are not used properly. Common mistakes include:

- Applying beads unevenly on the paint surface.

- Using too few beads, which reduces reflectivity.

- Choosing the wrong size of beads for the road type.

- Poor mixing of intermix beads, causing them to sink in paint.

Contractors should always follow correct application methods for the best results.

Future of Road Markings with Glass Beads

Road safety is becoming a global priority, and technology in road marking is improving fast. In the future:

- Smarter glass beads may be developed for longer reflectivity.

- Eco-friendly beads could reduce environmental impact.

- Advanced coatings may make road markings last even longer.

This means contractors who invest in quality glass bead solutions today will be ready for tomorrow’s safer roads.

Key Takeaway

Glass beads may be tiny, but they make a huge impact on road safety and durability. For drivers, they mean clear guidance at night and in bad weather. For contractors, they mean strong, professional, and long-lasting road marking solutions.